In the ten years up to 2013, there were nearly 200 mining deaths in the US that involved electrical safety in some way. This is despite some of the most stringent safety standards in the world.

Mines have always been dangerous environments when it comes to electrical safety, with the hazards coming from several sources. Sometimes the material being mined can be so flammable that a minor electrical spark or short circuit can ignite it. Equipment being used in confined spaces will often become hot, which can also be a source of ignition.

Planning electrical safety in mines

It is very often the dust and gas in the atmosphere of the mine that turns what should have been a minor electrical incident into a major explosion or fire. Here are some reminders about safe management:

1. Always consider the hazards in the mine and carry out detailed risk assessments for how electrical safety will be maintained.

2. If the atmosphere in the mine is highly combustible, electrical equipment should be intrinsically safe. This is explained in the next section.

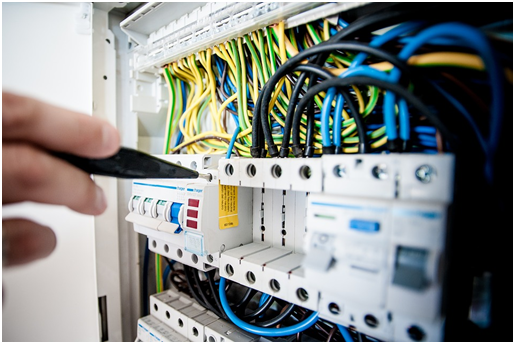

3. Many accidents occur during maintenance activities, so make sure that all electrical installations have been fully documented with detailed schematics.

4. Ensure that the general plans of the mine operation include detail on the electrical infrastructure and supply.

5. Use hazard tape within the mine to identify any areas in which there are buried or hidden cables.

6. Identify areas in which gases or dust could build up, and install warning signage.

7. Make sure that the ventilation and electrical engineers talk regularly and share information.

Intrinsically safe equipment

Electrical equipment for use in mines should be ‘intrinsically safe’. ATEX is the directive in the EU for designing electrical equipment that is intrinsically safe. There are various classifications according to the hazards the equipment is designed to control.

An ATEX certification means that equipment has been designed not to produce sparks in explosive or highly-combustible atmospheres. It is often the electrical control components, such as switches, that can cause arcing and sparking, so equipment for mines must be designed according to the ATEX intrinsic safety protocol. Such components are supplied by specialists such as http://www.osmelectrical.com.

All ATEX-certified equipment carries the CE marking, along with the ATEX hexagon and the equipment group and category.