When an appliance fails a test there is usually a reason as to why it failed. If you are responsible for the appliance, whether it fails or not, then you first need to suitably notify the designated company safety instructor. The appliance should then be removed and taken out of action, and investigated as to why it may have failed. Then it should be labelled with a safety sticker and barcode for easy tracking. It is important not to continue using an appliance that has failed a test because this can lead to potential electrical shocks or cause a fire hazard.

Possible reasons why an appliance might have failed a test are:

– There is a split in the lead. It may be that it just needs a replacement.

– The plug is cracked.

– There is an issue with the earth or the resistance – Which might warrant the appliance needing to be sent back to the manufacturer to be inspected.

Not all appliances that fail PAT testing are necessarily faulty. There are several other reasons as to why appliances may fail to test, such as:

– The equipment was not properly calibrated.

– The wrong equipment was used for the type of appliance.

It is best to rule out these potential issues before proceeding with a standard procedure with appliances that have failed a test. It is worth working alongside another PAT testing professional to help address any concerns more thoroughly.

Dealing with problems and finding solutions.

Most PAT testers and service providers who are fully competent and have the experience to test electrical appliances and putting them through relevant tests know that some types of equipment are prone to fail sometimes. These types of appliances then have to be tested using alternative tests to verify them.

Some appliances with inbuilt devices which limit the voltage like surge protectors seem to fail the Insulation Resistance Test. An appliance with a normal voltage of 500V/250V DC might be considered for an Insulation Resistance Test, core relay systems, as well as electromagnetic switches won’t always respond to the testing. Those electrical devices such as computers, televisions, and power tools will instead have to be put through a test called the Leakage Current Test. It works to clear them for safe use.

It is worth being aware that the sequence in which tests are carried out also helps to verify the overall effectiveness of the process of the testing.

The other typical problematic things that can arise from appliances are those that are designed with long extension cords tend to subsequently fail the Earth Continuity Pass Test. Though a competent PAT tester can usually help this common issue.

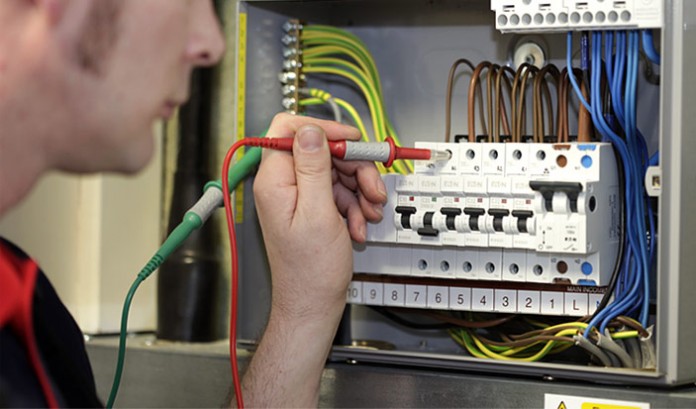

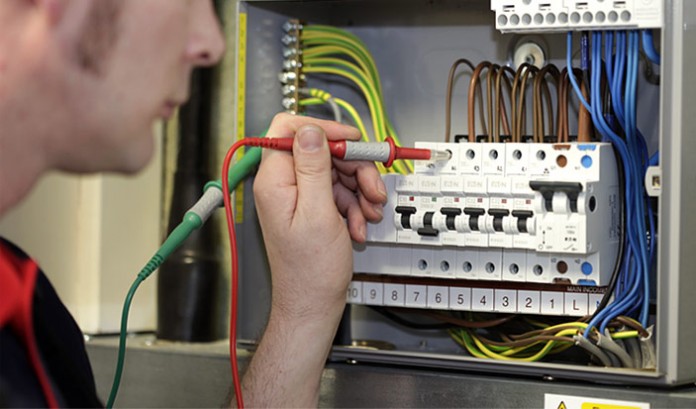

What does PAT testing involve?

The policy on routine PAT appliance testing safety checks are regularly performed on all electrical appliances. It is a fundamental safety guideline put in place to fully ensure that anyone working or tenants in businesses and homes, who may potentially come into contact with these appliances don’t come into the risk of harmful or fatal injury.

So it is paramount that PAT testing be performed on appliances consistently.

Though the law doesn’t legally state how regular PAT testing should be carried out, it makes sense and at the very least to do a yearly observational check. This will typically include the checking and testing for frayed wires, looking to make sure the casing around the appliance isn’t damaged in any way or coming undone, checking plugs to see if they appear to be damaged or cracked. Then a professional PAT tester will be able to determine the next form of action. They might need to repair the appliance if at all possible, or know another way to ensure the appliance is safe.

Testing Frequency

There are a few different factors as to determine how often you should have appliances tested.

– Equipment that is used fairly often should be tested more. It is more likely to suffer more damage than appliances that aren’t used as regularly.

– If someone notices damages as soon as they become noticeable. This will help prevent there being a lesser chance of a hazard happening.

Here are some recommendations for appliance testing at these places:

Offices and Shops – Class 1 equipment such as computers should be tested every 48 months.

Schools – All of Class 1 equipment should be PAT tested every 12 months. All Class 2 should be tested every 48 months by PAT professionals.

Construction – All equipment used on construction sites 110V equipment should be tested every 3 months.