Keeping your equipment clean is one way to ensure that it lasts and performs as it should over the long term. And when the equipment in question includes anilox rollers, it is especially important to establish an effective cleaning regime.

Anilox rollers are a dynamic area for business investment, and new developments in the technology are constantly evolving, as highlighted here:. It therefore stands to reason that any company that wants to get the best possible benefits from their anilox roller equipment should look for the very best methods to keep it in superb operating condition.

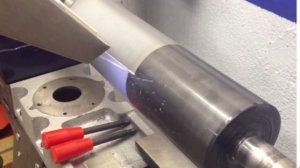

The Ultrasonic Method

The good news is that the latest ultrasonic technology delivers just such a cleaning experience. Thanks to the ultrasonic process, which utilises cavitation to provide a deep clean for every area of the rollers, you can expect a result that safely eliminates even the smallest contaminants without the risk of damage, such as abrasion.

That’s because ultrasonic anilox cleaning equipment works by applying a high pressure sound wave charge to a simple fluid bath, which converts into cleaning action through a transducer. The ultrasonic sound waves result in tiny bubbles, which effectively clean the surface area with a high level of precision, by imploding against the anilox rollers. Rather than relying on harsh cleaning chemicals or abrasive scrubbing action, these microscopic bubbles remove all dirt and contaminants, including oil, dust, pigments, rust, and grease, by sucking it away from the roller surface as they implode. This incredible process is known as cavitation, and you can learn more about it at specialist sites such as www.caresonic.com/.

Best For All Anilox Rollers

It’s clear, then, that the best anilox cleaning equipment will implement the ultrasonic approach. The technology is ideal for anilox rollers, which tend to be contaminated with ink coatings, with a water, solvent or UV base. By choosing the appropriate cleaning fluid for the ultrasonic bath, any of these ink coatings can be safely and accurately eliminated from chrome, ceramic and sleeve types of rollers, with superb results achieved quickly.